Prototypes and small series from sheet metal up to 8.0 mm sheet thickness

Our service portfolio extends to sheet metal parts for prototypes and small series. Especially in this area, quality plays a special role. A lot depends on the material, whether strengths, bending radii or spring properties. Here we access a pool of different possibilities.

Prototypes from auxiliary tools / crash mould tools

For high requirements, we also supply sheet metal parts manufactured using prototype tools. Here, similar conditions apply as with prototype tools for injection moulding: the effort is kept within narrow limits, just so that the required quality can be achieved. If necessary, the bending and embossing tools are used unhardened, with limited output of less than a hundred to several thousand pieces. Larger bending operations are done by machine, smaller ones by hand. In the end, you get your parts just as you need them. Fast, precise and cost-effective. All sheet metal parts are produced in the planned geometry and from original materials in series quality. This means that you can carry out functional tests on the finished component after only a short time. If the parts are OK, we often produce further sample parts or even small series from the prototype tools.

Prototypes also often without tooling costs

Due to the use of bending construction kit systems, we are often able to produce your sheet metal parts WITHOUT proportional tool costs!

The two key manufacturing processes we use to produce your prototype or sample are laser cutting and waterjet cutting. The use of lasers is ideal when thinner sheets are to be processed; typically sheet thicknesses of 0.2 to 2.0 millimetres. Waterjet cutting, on the other hand, offers the advantage that no thermal energy is applied to the material during the cutting process. Here, precise, economical cuts up to a sheet thickness of 4 millimetres can be realised without any problems.

Also available is the generative SLM-Procedure, which is ideally suited for small quantities.

Facts & Figures Prototypes made of sheet metal:

- Classically manufactured sheet metal parts from original material

- Sheet metal parts in series geometry

- Thread cutting, press nuts, pull-throughs

- Up to 8.0 mm sheet thickness

- Prototypes, small and medium series from just one tool

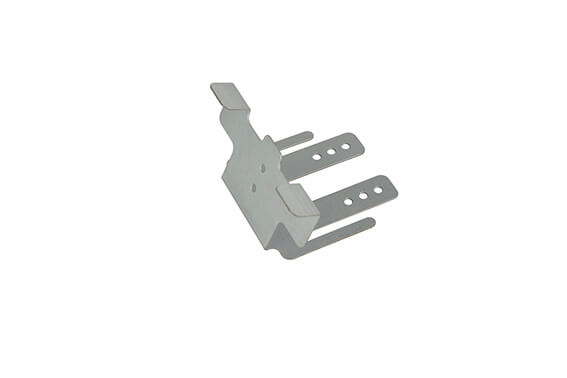

Mounting Plate

Pre-series

Process: Blank lasered, bending via

auxiliary tools

Material: steel KTL-coated, 280 copies

Realisation time: 3 KW

Halteblech

Pre-series

Process: Blank laser-cut, deep-drawing via auxiliary tools

Material: Steel KTL-coated, 300 pieces

Realisation time: 4,5 KW

Klemmstecker

Pre-series

Process: Laser cutting, folding

Material: Spring steel, 2000 pieces

Realisation time: 2,5 KW

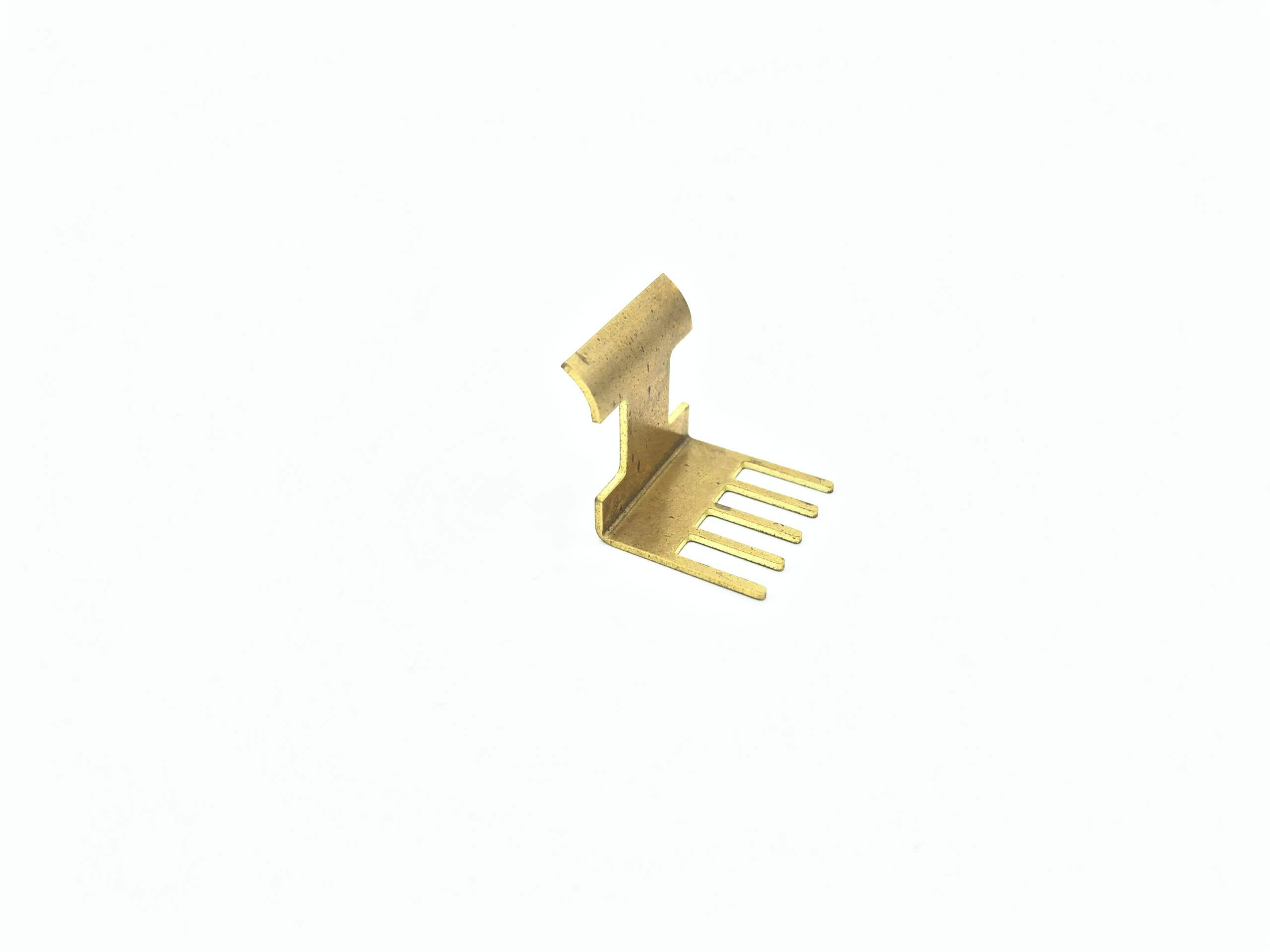

Gabelkontakt

Pre-series

Process: Blank lasered, bending

via auxiliary tools

Material: Brass, 10 copies

Realisation time: 2 KW

Request an offer for a prototype or small series production quickly and easily.

prototype or small series production!

Our experts and specialists will be happy to advise you. We strive to process your requests within one working day (24 hours) and create an individual offer based on your specifications and requirements.

We will be happy to advise you on your project in advance by telephone!

Request a quote now